3D Printing Materials

Industrial-grade 3D printing materials engineered for Markforged printers.

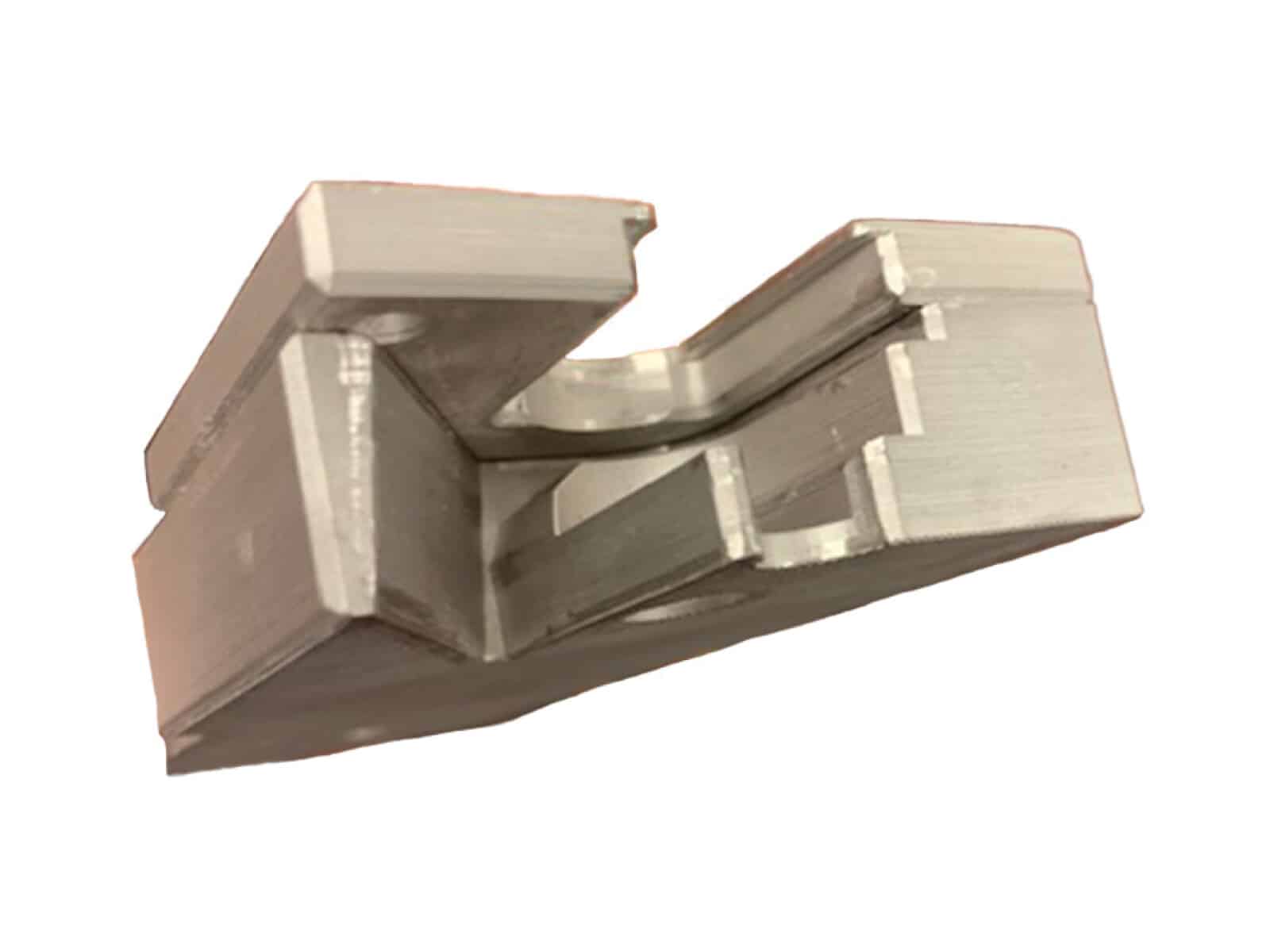

Metal

17-4 PH stainless steel combines high strength, corrosion resistance, and hardness making it widely used in aerospace, medical and petroleum industries.

Applications:

- End-of-Arm Tools

- Lightweight Brackets

- General High-Wear Tooling

- Functional Prototypes

- Custom Wrenches & Sockets

Pure copper conducts heat and electricity far better than traditional metals. Markforged Copper possesses better conductivity characteristics than alloyed copper that can be printed on DMLS machines. Unlike conventional fabrication processes which are extremely labor intensive and expensive, Markforged Copper is extremely simple to 3D print.

Applications:

- Welding Shanks

- Induction Coils

- Heatsinks

- Bus Bars

- Custom Fittings, Adapters, and EDM Electrodes

Inconel is a nickel-chromium based super-alloy that is highly resistant to harsh Corrosive and oxidative environments.

Applications:

- High-Temperature Fixtures

- Corrosion-Resistant Fittings

- Crucibles

- Turbine Hardware

H13 tool steel works excellently in high temperature and can withstand drastic Cooling. This, coupled with abrasion resistance and machinability, makes it ideal for molds and wear resistant pieces.

Applications:

- Cutting Tool Bodies

- Brazing Fixtures

- Mold Inserts

- Wear-Resistant Tools

- High-Strength Parts

A2 tool steel is air-hardened and has excellent impact resistance. great for Punches, dies and form tooling.

Applications:

- Forming Tools

- Stamping Dies

- Punch Dies

D2 tool steel is an air-hardened tool steel with high carbon and chromium content that trades toughness for great hardness and abrasion resistance.

Applications:

- Forming Tools

- Stamping Dies

- Punch Dies

Plastic

Nylon mixed with chopped carbon fiber offers a high-strength thermoplastic with excellent heat resistance, surface finish, and chemical resistance.

Applications:

- Plastic Part Replacement

- Housings

- Sensor Mounts

- Cosmetic Prototypes

Certified UL 94 V-0 rated nylon filled with chopped carbon fiber. Reinforce Onyx FR with continuous carbon fiber to be as strong as 6061 aluminum at half the weight

Applications:

- Weld Fixturing

- Aerospace Clips & Brackets

- Laser Marking Fixtures

- Energy/Electrical Brackets & Fixtures

Onyx ESD is a static-dissipative chopped carbon fiber nylon material, precision-engineered for a tight range of surface resistance. Onyx ESD meets ESD-safe requirements of the most stringent manufacturers, while offering the same industry-leading print quality of Onyx. Onyx ESD is stronger and stiffer than Onyx, with the same near perfect surface finish, making it suitable for advanced manufacturing applications from electronics assembly to industrial robotics and process automation.

Applications:

- Vacuum Grippers

- Transfer Tools

- Pick and Place

- Transfer and Packaging Trays

- Electronics Enclosures

ULTEM™ 9085 Filament is Markforged’s first high temperature printing polymer. It’s an extremely durable thermoplastic that exhibits excellent flame, smoke, and toxicity (FST) characteristics. Usable in production aerospace applications, ULTEM™ Filament brings Markforged’s CFR technology to a new realm of parts. ULTEM™ Filament is available in Markforged’s new 3200cc XL spool — four times larger than our standard spools.

Applications:

- High Temperature Tooling

- Aircraft Interior Paneling

- Aircraft Brackets, Handles, and Knobs

- Custom Ducting

- Composite Molds and Layup Tools

Smooth TPU 95A is a rubber-like material that when used with Markforged composite printers offers product developers and manufacturers the ability to create flexible, impact-absorbent parts on demand.

Applications:

- Seals and gaskets

- Shock absorbers

- Protective coverings

- Straps, bands, and drive belts

- Non-marring work holding and grips

- Wheels and treads

Precise PLA is our easy-to-print plastic for precision concept modeling and validation. Based on the most common 3D printing prototyping material, Precise PLA 3D prints without warping and comes in a variety of colors. Best of all, it’s affordable. So you can use as much as you need to fine-tune your designs before implementation.

Applications:

- Part prototypes

- Fit checks

- Color coded indicators

Nylon is an unfilled thermoplastic. It’s a non-abrasive material that is great for ergonomic surfaces and workholding for pieces that are easily marred. It can be painted or dyed.

Applications:

- Ergonomic Tools

- Assembly Trays

- Cosmetic Parts

Continuous Fiber

Carbon Fiber is Markforged’s unique, ultra-high-strength Continuous Fiber — when laid into a Composite Base material like Onyx, it can yield parts as strong as 6061-T6 Aluminum. It’s extremely stiff and strong, and can be automatically laid down in a wide variety of geometries by Markforged 3D printers. A special Carbon Fiber variant is compatible with ULTEM™ 9085 Filament.

Applications:

- High-Strength Tools & Fixtures

- Brackets & Mounts

- Inspection/CMM Fixturing

- Bespoke End-Use Parts

- Functional Prototypes

Carbon Fiber FR is a flame-retardant variant of Markforged’s unique, ultra-high-strength Continuous Carbon Fiber — when used to reinforce a Composite Base material like Onyx FR, it can yield parts as strong as 6061-T6 Aluminum. It’s extremely stiff and strong, and can be precisely laid down in a wide variety of geometries. Programmatically trace curved features, reinforce holes, and mimic unidirectional fiber layups — all within a few clicks.

Applications:

- Cabin Components

- Brackets & Mounts

- MRO & Spare Parts

- End-Use Parts

- Functional Prototypes

Kevlar® is tough, lightweight material, and can bend further than any other fiber, making it ideal for 3D printing.

Applications:

- End-of-Arm Tooling

- Stanchions, Cradles, & Supports

- Delrin® Part Replacements

- Wear Stops

HSHT fiberglass material delivers the highest impact resistance and heat deflection temperature of our continuous fibers.

Applications:

- Polymer Molds

- Prototype (Low-Run) Injection Molds

- High-Temperature Fixturing

- High-Temperature Prototypes

Fiberglass is Markforged’s entry-level Continuous Fiber —a material capable of yielding parts 10x stronger than ABS when laid into a Composite Base material like Onyx. Fiberglass is the flagship material of the Onyx Pro and X5 and printable on the Mark Two and X7, providing a more affordable alternative to Carbon Fiber.

Applications:

- Softjaws

- Medium-Strength Tooling

- Insulative Reinforcement

- Hand Tools